- Home

- Plastic Mold Manufacturing

Plastic Mold Manufacturing

Specializing in the design and production of injection molds, we can manufacture household appliance molds with specular highlights along with automobile molds, and precision molds, etc. Our production facilities can produce 500-800 mold sets annually, with the maximum weights reaching 50 tons.

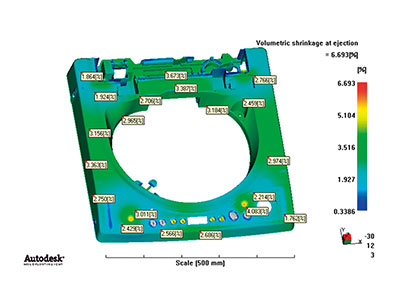

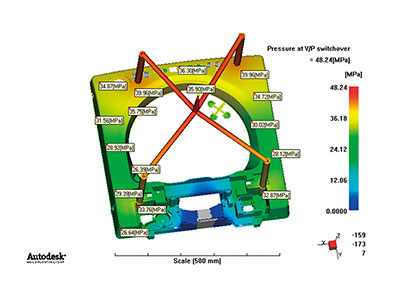

- Mold Designing

We are a professional plastic mold manufacturer skilled with CAD and CAE (computer aided engineering) for mold designing. We also use specialized software to help and guarantee the mold designs. This allows us to fulfill accurate simulations of both exterior and interior mold sections.

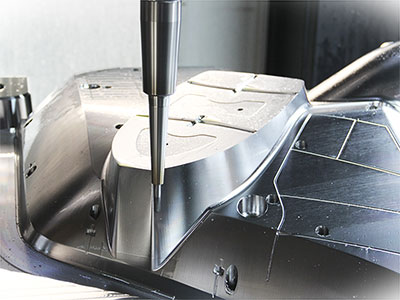

- CNC Machining

We are abundantly equipped with computer controlling machines. This includes 6 milling machines, 12 CNC machines, 8 machine for 5 axis, 3 wire cutting machines, 2 milling and grinding machines, and 1 laser welding machine. We can accurately manufacture plastic molds through the data made by CAD and CAE software and produce 800 sets of molds every year.

- Experienced Plastic Mold Makers

We have a team of professionals experienced in the designing, manufacturing, and assembling of plastic molds for over 10 years. Our senior professionals have over 20 years of experience. Their skillset in making plastic molds allows them to create high quality and precise products.

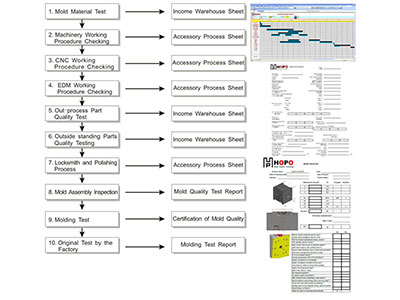

- Quality Control

Being fully aware of product quality affecting the survival of a company, we emphasize great importance to quality inspections, ensuring the quality of our molds. Our well-trained inspection personnel carry out quality inspections of each link from raw materials and CNC machined workpieces in strict accordance with the quality management processes.

- High Efficiency Saving Your Cost

Our standardized factory management can help improve efficiency, thus saving unnecessary expenses and reducing product cost.

We understand that the production costs for mold making contributes to production efficiency. This includes related costs which pertain to mold steel, logistic, power consuming, and stuff payment. Therefore, we focus on every detail of efficient spending to improve supply chain costs.

-

We pride ourselves on the principle of "satisfying our customers’ demand with professional solutions". In order to achieve this goal and better serve our customers, we have imported more than 20 sets advanced large-scale precision CNC machining equipment, EDM machines and milling facilities. On the other hand, we set up a complete CAD / CAM / CAE system to get a better guarantee of the accuracy.

We adhere to a strong business motto of "responsibility, attitude and details oriented", and we always focus on core team building. -